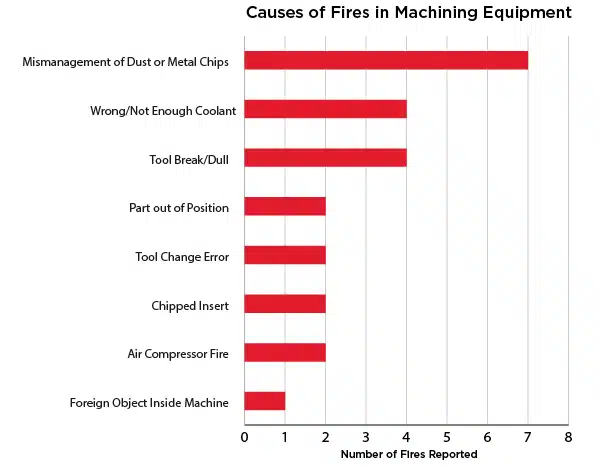

Most experienced machinists have seen at least one fire on the job. Cutting metals at high speeds creates plenty of opportunities for sparks to ignite flammable materials. Many fires in machine shops are preventable, either by minimizing sparks or making sure they do not ignite flammable materials. But mistakes can happen. Our analysis of 24 fires in machine shops shows that one mistake, in particular, causes almost 30% of all fires.

Our research shows that the leading cause of machine shop fires is mismanagement of dust and/or metal chips. Our findings were gathered from reports of fire incidents in the news, on social media, and interviews with our customers, who have had fires suppressed by CNC fire suppression systems.

The reason that mismanagement of dust or metal chips causes so many fires is that when dust or metal chips accumulate, it is easy for a spark to catch them on fire. Metal chips collect in chip pans when not cleaned regularly. Shops should prioritize regular cleaning of chip pans, especially when machining multiple different materials. Similarly, when disposing of chips in a chip bin, it is important to keep the bin away from machines that might throw sparks. Chip bins should also be kept free of trash and other debris. Filters and dust collectors can help contain flammable dust from processes such as deburring. Consider using flame retardant filters for extra protection.

The next most common cause of fire is a tie between tool breaks and coolant errors. When a machine tool breaks, it can crash into another tool or otherwise malfunction, which typically produces a lot of sparks. In turn, the sparks can ignite the part being machined or – more frequently – ignite the coolant, which typically has a lower flashpoint.

Improper use of coolant can also lead to a fire. Coolants dissipate heat, so if you do not use the correct amount, then heat can build up and start a fire. This is especially true in high-speed machining applications. Pay attention to the type of coolant you are using: oil-based coolants are not as effective at dissipating heat compared to other types of coolants. If you are using an oil-based coolant, be aware of the fire risk, especially when running a new program using oil as the coolant. Clean agent fire suppression systems are highly effective at putting out coolant fires. The right kind of fire extinguisher can also be effective if used quickly by a trained operator.

The top three causes of fires in machine shops contribute over 60% of all fires analyzed. Other reported causes of fire include:

All fires start due to a combination of heat (or sparks), a fuel (such as oil coolant), and oxygen. The common causes of fires in machine shops typically introduce one or more of these fire risk elements. For example, a part that is out of position generates heat and sparks.

While a fire can happen in any machine shop, some shops are at higher risk than others due to the type of parts they are machining. Precision machine shops working on aerospace and medical parts work with more oil-based and high-pressure coolants, for example. Shops running jobs with long cycle times, especially those that run machines unattended, have to be extra vigilant about addressing fire risks. A fire may have time to grow before someone notices it. Finally, pay special attention to fire risks when running a program for the first time. It can be hard to predict the effect that new a program will have on your coolant and tooling, so proceed with caution, in case of something unexpected.

As OSTİM Defense and Aerospace Cluster (OSSA), we held a cooperation meeting with the Ministry of National Defense General Directorate of Technical Services. The opening remarks were delivered by OSSA Chairman of the Board, Mr. İbrahim Yarsan; ASFAT General Manager, Prof. Dr. Mustafa İlbaş; and Major General Ercan Eroğlu, General Director of Technical Services at the Ministry of National Defense. Following the opening session, experts from the Ministry of National Defense delivered informative presentations on “Introduction to MoD Military Factories” and “MoD Facility Security Clearance / Production Permit Certificate Processes.” As Nero Industry, we had the opportunity to present our products and capabilities to the MoD delegation and engage in bilateral cooperation meetings throughout the program.

*Legal Notice and Intellectual Property Disclaimer:

The entire content of this website including but not limited to all textual content, graphics, logos, images, photographs, illustrations, technical and scientific drawings, audio and video clips, animations, audiovisual recordings, software, source code, databases, design elements, user interface components, and all other technical and creative materials, together with all associated intellectual and industrial property rights is the sole and exclusive property of NERO Industries Defense Inc. or its duly authorized licensors. Such content is protected under the applicable laws and regulations of the Republic of Turkey, including but not limited to the Law on Intellectual and Artistic Works (Law No. 5846), the Turkish Commercial Code, the Turkish Penal Code, as well as all relevant international treaties and conventions to which the Republic of Turkey is a party, including but not limited to the Berne Convention for the Protection of Literary and Artistic Works, the Paris Convention for the Protection of Industrial Property, the TRIPS Agreement, the WIPO Copyright Treaty, and relevant European Union Directives and Regulations, whether currently in force or entering into force in the future. Unless expressly authorized in writing by NERO Industries Defense Inc., any reproduction, modification, transmission, dissemination, republication, uploading to other platforms, storage, public display or performance, commercial exploitation, or any other form of unauthorized use, whether in whole or in part, directly or indirectly, verbatim or in altered form, of the above-mentioned materials is strictly prohibited. Furthermore, any facilitation, encouragement, or promotion of such unauthorized acts is equally prohibited. Any infringement of these rights may constitute a violation of intellectual property and/or unfair competition laws and may result in civil and/or criminal liability under applicable national and international legal frameworks.

Nero Industries develops fire suppression systems, CBRN, laser warning systems, smoke launchers and military generators as one of Turkey’s leading defense industry manufacturers.

NCAGE CODE: T9830