Adjustable Pressure Relief Valve

Adjustable Pressure Relief Valve

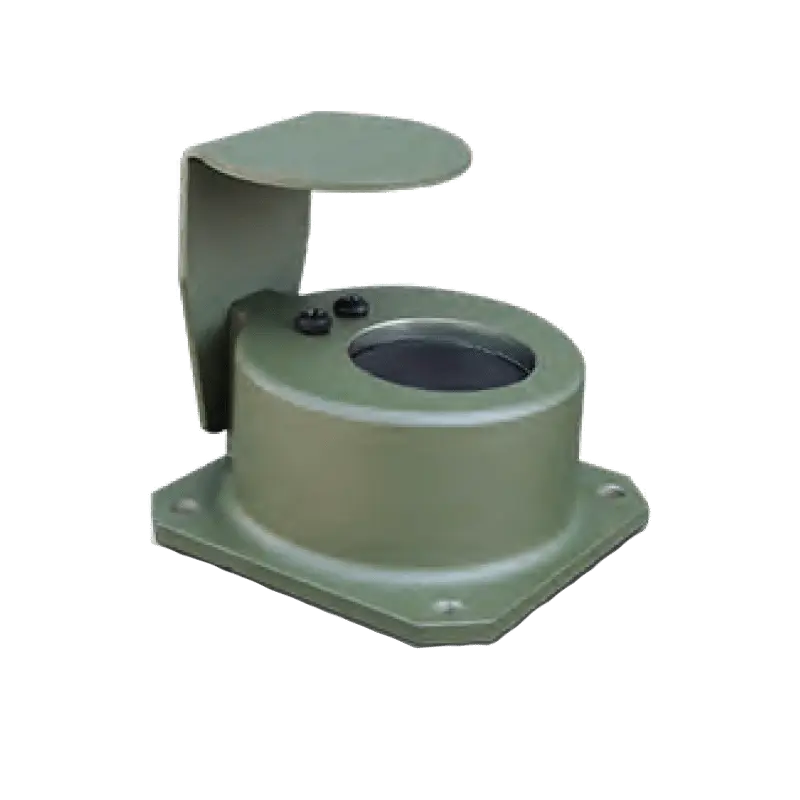

Adjustable Pressure Relief Valve is a mechanical safety component designed for positive pressure CBRN systems operating in accordance with NATO AEP54 standards. The valve is used to discharge excess internal pressure in a controlled manner, ensuring stable overpressure conditions within sealed vehicles or protected enclosures.