Fire is the second most common type of catastrophic wind turbine accident behind blade failure. However, by understanding and addressing fire risks, you can mitigate or even prevent fire damage in wind turbines. We will explore some of the reasons why wind turbines catch fire and options for mitigating risk.

Why Wind Turbines Catch Fire

Wind turbines catch fire because components inside the turbine fail, generating heat or sparks and igniting flammable materials. Among wind turbine components, converter cabinets and capacitor cabinets catch on fire most frequently. Fires can also start in the wind turbine’s transformer or in the emergency brake behind the gear box. While some fires are caused by component failures, others result from lightning strikes.

Fire suppression systems can keep turbines and the people that work on them safe by detecting and suppressing fires in the incipient stage, before they spread. It’s important to detect and fight fires in the early stages of a fire to minimize damage. These systems may be installed anywhere that a fire can start in a turbine. Other products help protect wind turbines from damage caused by lightning strikes.

Fires in Converter Cabinets and Capacitor Cabinets

According to Renewable Energy Loss Adjusters (RELA), electrical faults are the leading cause of fires: “This involves anything from short circuit, overloading, cable failure and crimping failure to generator failure” (GCube Insurance, 2015).

The most common place for an electrical fault in a wind turbine is the converter cabinets and capacitor cabinets in the nacelle. When an electrical fault produces an arc flash or sparks, the electrical cabinets may catch fire. Fires originating in the converter and capacitor cabinets can quickly spread to the rest of the nacelle. Fires in the wind turbine’s nacelle are very difficult to fight, as the nacelle is over 300 feet above the ground. Most firefighters let a nacelle fire burn and focus on fighting the resultant brush fires on surrounding land. 90% of all fires in a wind turbine nacelle destroy the turbine completely.

Fires at the Nacelle Brake

The nacelle brake, which is commonly found behind the gearbox, is another component that could catch fire. In an emergency, the nacelle brake stops the turbine’s blades from spinning. The mechanical braking system can generate a huge amount of friction and heat, sometimes resulting in a fire. Newer turbines may feature electric braking systems, which are less susceptible to fire. However, mechanical brakes are often used as back ups to electrical braking systems.

Wind turbine transformers, located in the nacelle or at the base of a turbine, are a third ignition point for wind turbine fires. Transformers convert energy into the appropriate voltage for the electrical grid. Electrical faults in the transformer, like faults in the converter and capacitor cabinets, can lead to a fire. Additionally, some transformers contain flammable oil, which increases the likelihood that a fire will start or spread in this area of the turbine.

Fire Protection for Wind Turbines

Wind turbines are expensive and valuable pieces of equipment. According to GCube insurance, the average wind turbine fire costs $4.5M. Other estimates from a recent webinar suggest the average is $7-8 million. Fires in wind turbines can also put wind turbine technicians at risk and even cause wildfires in the surrounding area.

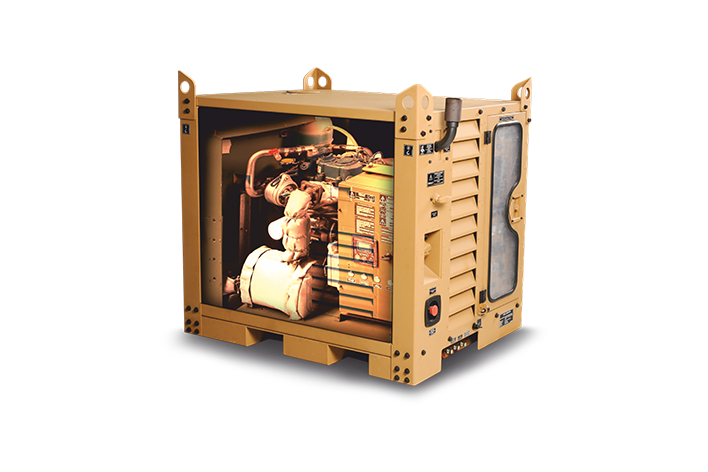

Traditional sprinkler systems are impractical for wind turbine fire protection. However, a special hazard fire suppression system can be easily installed to protect ignition points in a wind turbine. These systems are modular and can be customized to protect specific components, including the converter and capacitor cabinets, the transformer, and the nacelle brake.

EN