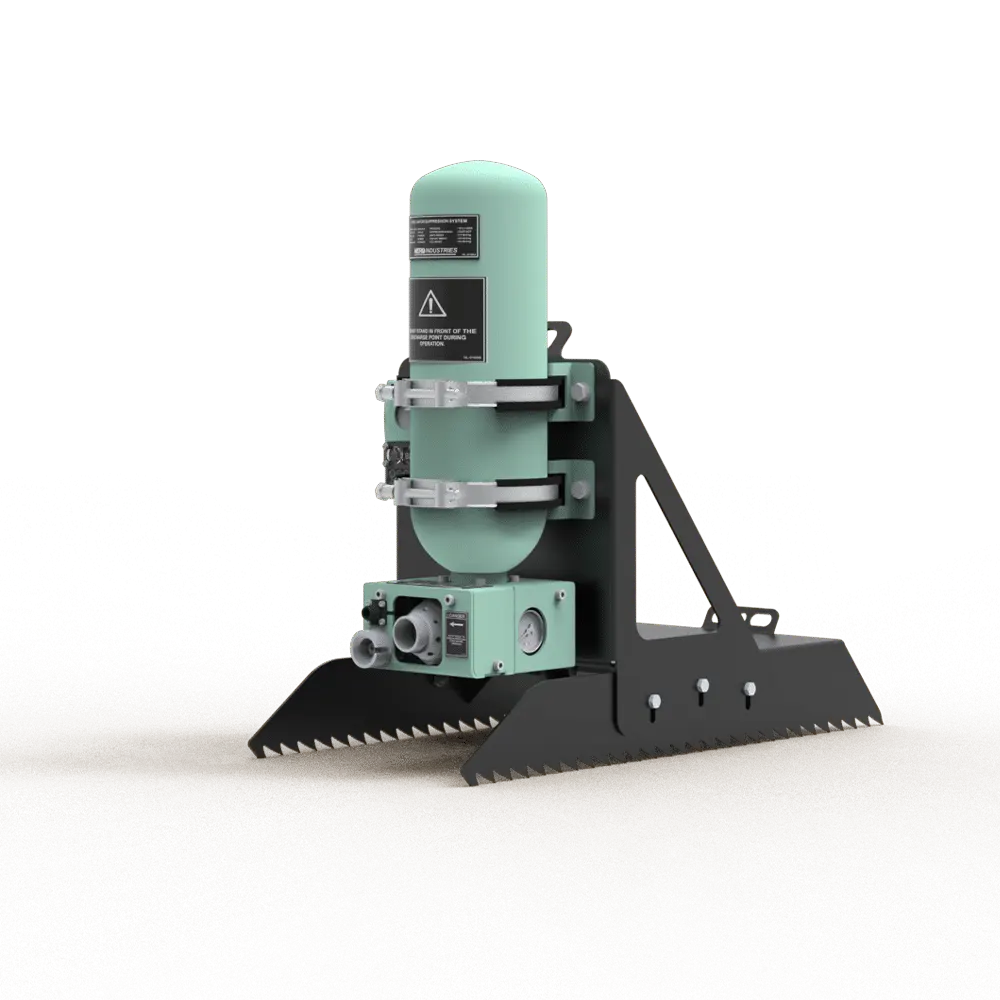

Toxic Vapor Suppression System (TVSS)

TVSS is developed to neutralize toxic vapors and hazardous fumes generated by chemical agents or industrial substances. By deploying a defined quantity of decontamination agent within seconds, the system supports early intervention and mitigates secondary contamination risks during emergency response operations.

Where to Use / Deployment

The system is suitable for deployment in military platforms, critical infrastructure protection zones, industrial facilities, shelters, and open or semi-confined areas exposed to chemical vapor threats. Its portable and self-contained structure allows installation on fixed platforms or use as a standalone suppression unit in diverse operational environments.

System Configuration and Structure

TVSS utilizes a portable cylinder containing Fast-Act decontamination agents. The system is capable of deploying up to 2 kg (approximately 4.4 lbs) of decontamination agent in under two seconds. The design is maintenance-free, eliminating the need for routine servicing and enhancing long-term operational reliability.

The system structure supports rapid activation and controlled dispersion, enabling efficient coverage of the targeted area while maintaining predictable suppression performance.

Activation and Dispersion Mechanism

The system can be activated either electrically or via an integrated detector. Upon activation, a pyrotechnic mechanism releases pressurizing gas, generating the required internal pressure to disperse the decontamination agent effectively. This design removes the need for external pressure sources and supports autonomous operation under emergency conditions.

Functional Role

TVSS rapidly disperses a fast-acting decontamination agent to suppress toxic vapors and hazardous fumes remaining after chemical release events. By combining fast deployment, maintenance-free operation, and autonomous activation, the system enhances personnel safety, supports effective incident response, and reduces the operational impact of chemical and CBRNE threats.

Frequently Asked Questions (FAQ)

TVSS is designed to rapidly suppress and neutralize toxic vapors generated during chemical and CBRNE incidents.

The system can deploy up to 2 kg of fast-acting decontamination agent in under two seconds.

No. The system is maintenance-free, which increases reliability and simplifies long-term operation.

TVSS can be activated electrically or through an integrated detection-based trigger mechanism.

It can be used in military platforms, critical infrastructure areas, industrial facilities, shelters, and open or semi-confined environments exposed to toxic vapor threats.