Deflector

Deflector

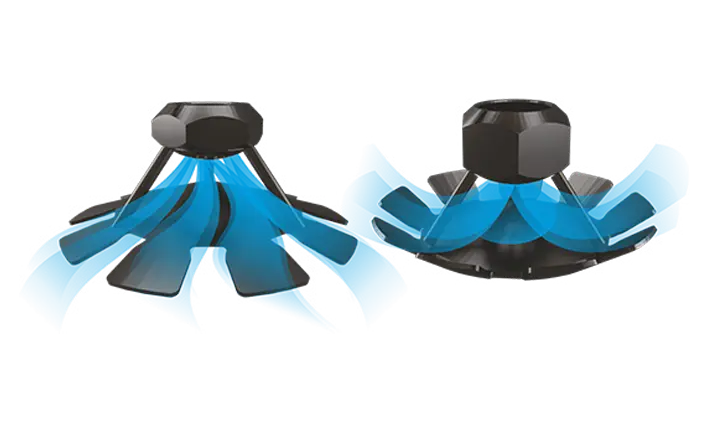

Vehicle-mounted fire suppression systems require rapid and uniform distribution of extinguishing agents to eliminate fire risks effectively. The Deflector Unit is a critical component integrated into such systems, engineered to deliver full 360° multi-directional dispersal. By redirecting and diffusing the extinguishing agent upon cylinder activation, it ensures comprehensive coverage across enclosed or semi-enclosed vehicle compartments.

Deflector

The Deflector Unit functions as a passive flow distributor within fire suppression systems. When the fire-suppression cylinder is activated, the pressurized extinguishing agent is routed directly into the deflector. Its multi-fin geometry redirects and disperses the agent radially, enabling rapid and uniform distribution throughout the protected area.

This operating principle maximizes coverage efficiency and supports effective fire neutralization by eliminating blind zones within vehicle compartments.

Design and Material Structure

The Deflector Unit is manufactured from high-strength, heat-resistant engineering polymers, such as PA6/ABS military-grade composites. This material selection ensures durability, impact resistance, and vibration tolerance under harsh operational conditions.

The unit features a matte black, low-glare tactical finish, supporting integration into military vehicle interiors without causing unwanted reflections.

Distribution Performance and Coverage

Designed to provide full-spectrum 360° radial dispersal, the Deflector Unit ensures uniform agent saturation across critical compartments. Its optimized flow geometry enables rapid deployment of the extinguishing agent, supporting immediate thermal suppression and efficient flame disruption.

The deflection angle can be adjusted upward or downward based on system tubing configuration, allowing adaptation to different vehicle layouts and compartment geometries.

Structural Characteristics and Integration

The Deflector Unit typically incorporates 6 to 8 directional fins to achieve optimized agent distribution. It is compatible with standardized nozzle and tube connections used in vehicle fire suppression systems, enabling seamless integration into existing system architectures.

With a net weight of approximately 390 grams, the unit offers robust performance without imposing excessive load on the system.

Installation Areas and Application Domains

The Deflector Unit is intended for installation in areas such as the roof, upper compartments, or nozzle exit interfaces within military vehicle interiors. It is widely used in armored personnel carriers, infantry fighting vehicles, tactical armored trucks, MRAP platforms, military transport and logistics vehicles, enclosed engine cabins, power modules, and auxiliary equipment compartments.

Operational Reliability in Military Environments

The Deflector Unit is designed to operate reliably within an operational temperature range of –20°C to +80°C, aligned with common military environmental standards. Its geometry and material structure are optimized to maintain dispersal performance under vibration, shock, and movement typical of military operations.

By ensuring rapid agent diffusion and uniform coverage, the Deflector Unit enhances the survivability of critical onboard systems and contributes directly to vehicle and personnel safety.